English

Views: 2 Author: Site Editor Publish Time: 2022-04-19 Origin: Site

The gate valve has a simple design and is used to regulate the flow of the working medium in the pipeline. It is used in all areas of industry and everyday life - from wastewater treatment to the transport of petroleum products.

The installation of a sliding or "knife" valve is very simple. it includes:

From the body, this is a t-shirt with a central extension and hollow branches. Can be equipped with a cover.

seat. These elements perform the guiding function and ensure the tightness of the shutter.

Closing device (flaps). This element is located perpendicular to the flow of the medium and regulates the capacity of the valve.

The rod at the top of the case is responsible for moving the flip cover.

The control mechanism is a screw, a lever, and a driver.

Gland unit to ensure the tightness of the rod housing pair.

Gate valve advantages and disadvantages of this device:

The main advantages of this valve are its simple design, low hydraulic resistance and it can be used to transport media with solid inclusions.

The disadvantage is that the sealing degree is low and the construction height is large. Such products must not be used to transport hazardous substances whose leakage may be severe.

There are two types of gate valves for chimney, water supply, and plumbing systems: wedge and knife.

This type of reinforcement has two saddles, angled to the body and facing each other. The bolts are wedge-shaped and placed between the saddles. There are three types of blinds:

With rigid wedges , in the form of veneers with different thicknesses. Need to adjust.

With double disc wedges . In this case, the wedge is a collection of two smooth discs rigidly held at a specific angle. This shutter has a more complex design, but is much simpler to install and operate than rigid wedges.

With elastic wedges . This shutter has two elastic discs that can be adjusted to the angle between the saddles. They can operate under significant changes in temperature and pressure.

Wedge valves are not used for the transport of hot media, nor in technical pipelines that transport media with a large number of solid inclusions.

The "knife" door has two saddles on the access holes in the body. The bolt is a thin plate that shuts off the flow.

There is a difference between a one-leg valve and a two-leg valve. The first is a combination of a knife and two saddles in the body, the second is two parallel knives with rigid fixation. The latter is characterized by better sealing and is used for industrial purposes.

Different types of actuators are used to adjust the operation of the mechanism. This is due to the different capacities of the pipes and the different densities of the working medium.

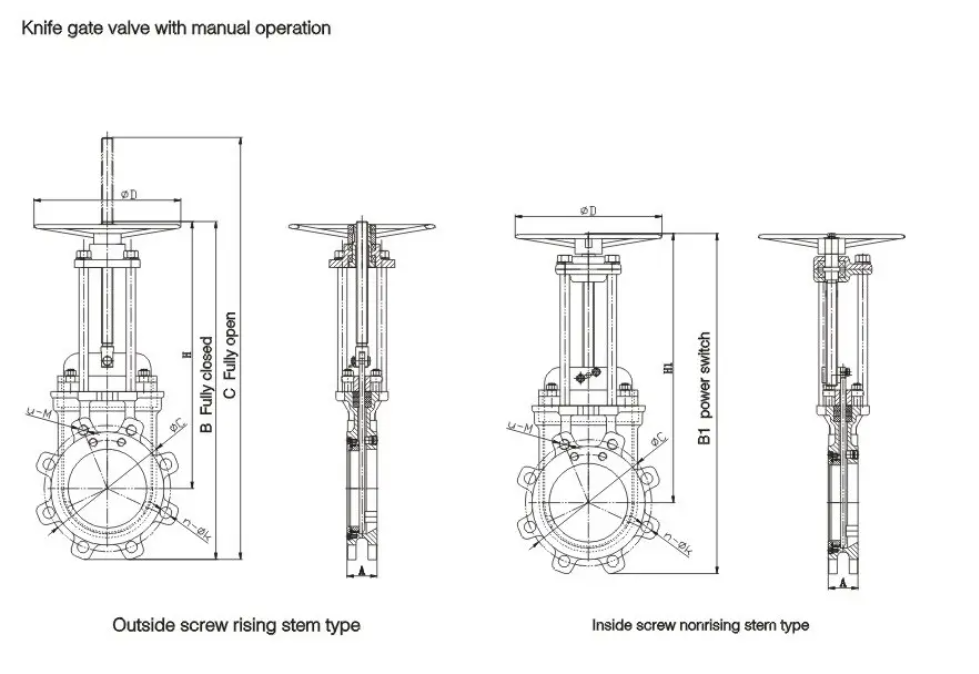

By manual method, the gate valve is adjusted using a handle or lever. It is installed on pipelines conveying liquids and low-density gases without solid inclusions.

Electric actuators allow you to adjust the position of the damper without physical effects. This valve is used in large enterprises to regulate the flow of viscous loose media with solid inclusions.

Pneumatically actuated valves have the most complex designs. They provide optimum sealing and are pipe mounted, remotely adjustable allowing manual control.

The gate valve can only block and regulate the flow of the working medium in the pipeline. Many variations in design features and rebar properties allow you to use in your organization:

water supply, sanitation (domestic and industrial);

natural gas and oil pipelines;

Wastewater treatment systems;

Pipelines for the mining industry;

Production of consumer goods. food and family;

ventilation.

Slide valves are the least used in water system design. Wedge reinforcement is most commonly used for them.

Another field of application for "knife" valves is in chimneys. It was in this area that the first door fittings were used. It has a very simple design with no seals, control elements, and consists only of a saddle and a knife.

Modern chimneys are also equipped with gate dampers (especially for solid fuels), but their design has been revised compared to the first.

The flue shaft and rectangular exhaust structure use cast iron knife valves, the round chimney needs improvement - where a saddle connection is installed. In the latter, a throttle rotary damper can also be installed, allowing you to adjust the flow.

Bi-directional knife gate valve

Gate valves can be installed on the pipeline in four ways: by welding, flanged, threaded or embedded methods. When welding, the connection scheme of the gate valve is as follows: Weld both ends of the pipe with the valve pipe to obtain a sealed continuous connection.

Flanges allow you to organize collapsible connections. Pipe parts and fittings with flanges are screwed with bolts or studs.

The threading method is rarely used. The installation of the valve is carried out with the help of the fixing nut. The main disadvantage is that the connection is weakened during the operation of the pipeline due to the effect of vibration. The knot needs to be tightened periodically.

Using the drop-in method, the valve body is installed horizontally between vertical sections of a pipe or mine and then glued. This method is only used for flue installations.

Depending on the installation method, the following are distinguished:

The clutch valve has a mature body with branch pipes. Can be flanged, welded or screwed;

between us. In this case, there are no branches on the valve body. Sometimes it's just a frame with a saddle. Flaps between flanges are installed in grooves in pipe sections or chimneys. Connections - flanged, welded, embedded methods.